Repair Case Study

Over time, catalytic heaters (particularly those near the bottom of an oven) can become contaminated with dust, powder or over-spray, especially if a the house-keeping in the paint shop or catalytic box oven is not what it should be. This can result in poor heat output, less uniform surface temperatures, wasted fuel and lost production.

Thermo Catalytic Systems Ltd.’ personnel are trained and certified to open up contaminated or punctured catalytic heaters and patch or fully replace the catalyst pad, restoring the heater to “like-new” performance. This is usually done in our own facility. However, to minimize down-time we sometimes arrange to do it in the customer’s premises.

In the example below, a 12″ x 60″ heater has been badly contaminated with white paint from a curtain coating machine on a skirting board production line, smothering the catalytic pad.

1. Before: The heater is so badly contaminated as to be useless.

1. Before: The heater is so badly contaminated as to be useless.

2. During: The heater is drilled open, the contaminated catalytic pad is replaced with

2. During: The heater is drilled open, the contaminated catalytic pad is replaced with

a new pad.

3. Completion: The heater is then fitted with a new wire mesh and carefully riveted back together.

3. Completion: The heater is then fitted with a new wire mesh and carefully riveted back together.

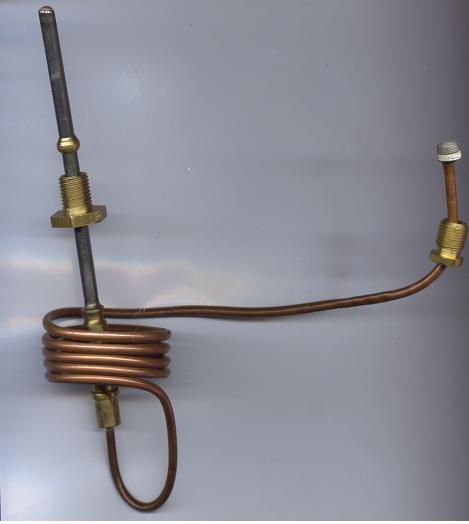

4. Testing: All heaters are bench- tested for gas

4. Testing: All heaters are bench- tested for gas

tightness, temperature and combustion efficiency before being returned to the customer.